Our Quality Assurance Framework

Strict Quality Objectives

≥95% customer satisfaction

≥99% finished product qualification

≥95% on-time delivery, zero fire/safety accidents

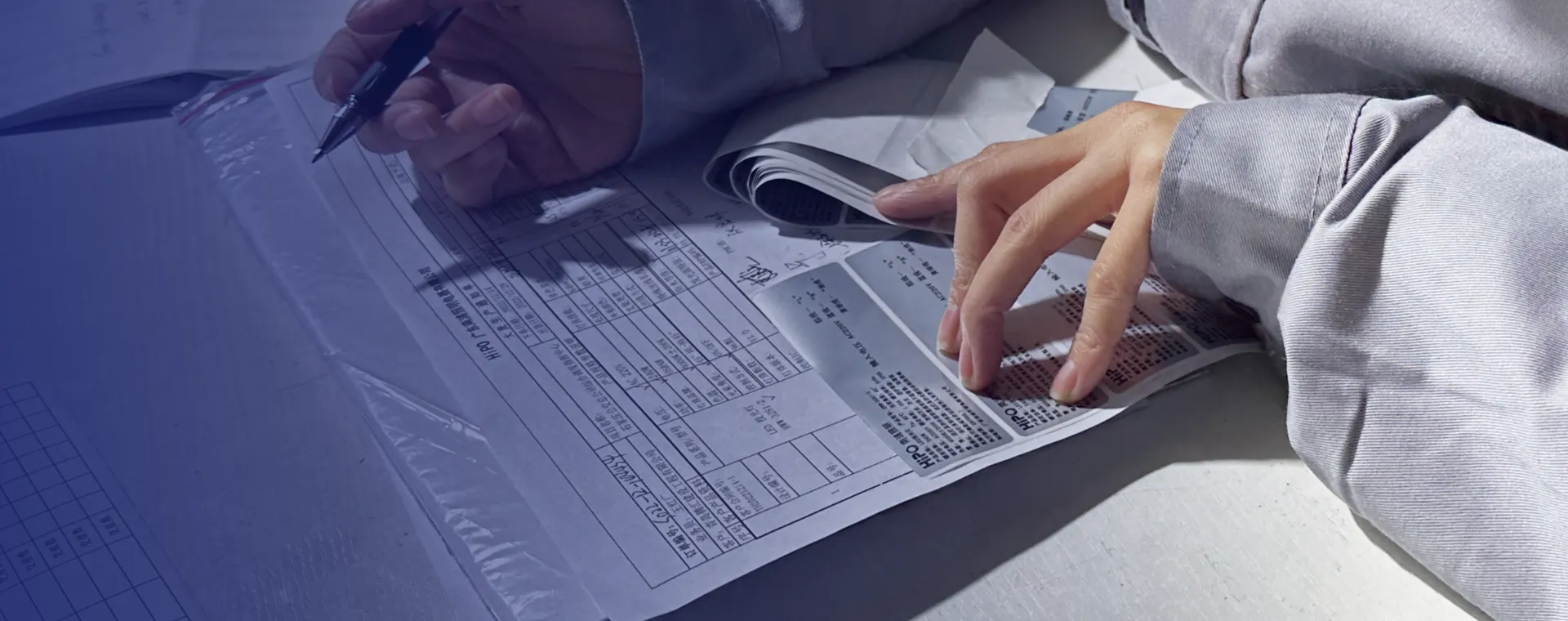

Rigorous Inspection Processes

IQC for raw materials, IPQC during manufacturing,

FQC for finished products, and OQC before shipment.

RMA Processing Flow

Customer submits application

After receiving the customer's request for defectiveproduct handling, the salesperson will convey it tothe relevant department, indicating the productfailure phenomenon, model, batch and purchasereceipt.

HIPO will audit

1. Customers send photos and videos of defectiveproducts and return the defective products ifnecessary.

2. Quality personnel will verify whether the product is within the warranty period: distinguish the responsible party.

Problem solving

Customer usage problem: HIPO provides technical support and helpssolve problems.

Product quality defect: If necessary, customers must return defectiveproducts first , and HlPO will reissue newproducts or deduct the equivalent amount fromthe next order.

100% Testing for Critical Parameters

Including pressure resistance, power, aging, waterproofness, insulation, and grounding.

Advanced Testing Equipment

Optical testers, temp/humidity chambers, integrating spheres, salt spray testers, EMC testers, RoHS testers, and cyclic aging testers.

Contact Us

Use Our Customized Support to Secure Opportunities

Start Your Custom Luminaire Project